Hot Water Boiler with Wood Waste as Fuel

- Description

Product Description

XNH wood thermal modified system heated by hot-oil or electricity is independently developed by Institute of Drying Technology of Nanjing Forestry University and Jiangyin XINAN Drying Equipment Co., Ltd based on careful study of existing high temperature heat treated equipment abroad. XNH wood thermal modified system has two structures: all-aluminum assembled kiln and carbon steel and stainless steel composite cylinder.

In order to solve the problem of residue disposal, XINAN developed hot water-heating system using wood residue as fuel to supply heat for wood drying, paint drying, workshop heating, etc. This system is safe and reliable, and features energy and capital saving, coolant and water saving, and low running cost. It has wide usage, high thermal efficiency, generates zero pollution and keeps temperature stable.

Power Saving

The hot water that circulate in the airtight system generate nearly zero waste, and no steam and hot water are wasted. The system can save 20-40% of fuel than the steam heating system.

Safe and Reliable

The condition in the kiln is easily controlled, as the heat is precisely controlled and temperature of the drying medium is stable. The hot water system is at normal atmosphere. If water leaks out, the whole volume is almost of no change. Thus the system is very safe and reliable and has no danger to explode.

Capital Saving

The cost of equipment and fixing is low because the structure of hot water boiler is simpler than that of steam boiler. The system saves coal as it uses wood waste as fuel. Hot water is used repeatedly so it saves water and cost of running the system. The boiler is horizontal and has double-running route, gas and fired tube. The gas from the boiler has no sulfur because of efficient dust remover. It is highly efficient and environmental friendly.

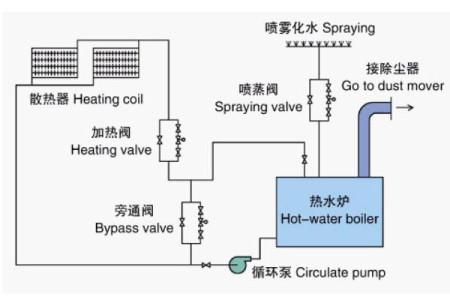

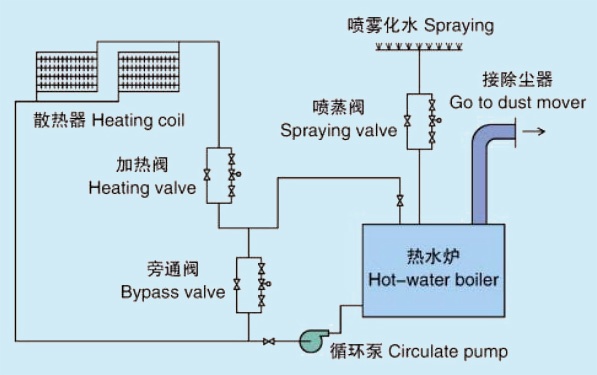

Hot Water Circulating System

The heated water is purged from boiler to the heating coil, and comes back after heat exchanging. The general tube is in charge of dispatching heat when several kilns need to be hated simultaneously. When none of them needs be to heated, the valve on the bypass pipe is opened automatically and the hot water comes back to the boiler directly. The Inflation tank is placed in the boiler. The problem of inflation of water can be solved through changes of water level.

The Automatic Screw Transporting System

The central dust removing system may manually move the wood waste to the large volume silo. The feeding speed can be adjusted evenly sending the waste to the boiler to ensure complete combustion. The large pieces of waste can be putted into the burning chamber through the boiler door by hand.

Types of Hot Water Boiler

| Hot water boiler | Capacity of wood can be dried (m3) | Thermal power (MW/h) |

| CDZG 0.35-95/70-M | 60–100 | 0.35 |

| CDZG 0.70-95/70-M | 150–200 | 0.70 |

| CDZG 1.05-95/70-M | 200–300 | 1.05 |

| CDZG 1.40-95/70-M | 300–400 | 1.40 |

| CDZG 2.10-95/70-M | 400–600 | 2.10 |

| CDZG 2.80-95/70-M | 600–800 | 2.80 |

Related Products

Read MoreQuick View

Read MoreQuick ViewAutomatic Wood Drying Control System (XINAN)

- high definition LED screen

- multiple human-machine interface, automatic control of each actuator in the kiln

- memory after power failure and alarm of abnormal state

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewTemperature, relative humidity and moisture content

- Six pairs of moisture content probes, 2 or more pairs of temperature and 2 EMC probes in every kiln.

- The probes are made of stainless steel and joints are imported to ensure accurate measurement.

- Signals are transported through special high temperature-resistant cables.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewVent Motor

- The motor can be turned 0 to 90 degrees based on humidity inside in the kiln.

- Automatic and manual operation can be switch outside of the kiln.

- Made in Korea or Switzerland with superior performance and high reliability. The twisting torque can reach 16NM.

Read MoreQuick View

Read MoreQuick View

Read MoreQuick ViewCirculating Fan

- The circulating fan has size 6 (Φ 600mm), 8(Φ 800mm), and 10(Φ 1000mm).

- The circulating fan is made of aluminum alloy adopting technology from Germany.

- The fans features scientific dynamic and static balance tests, big air volume and high air pressure, and can run clockwise and counter-clockwise.

- The motor is waterproof, high temperature-resistant and exempted from customs check.

Read MoreQuick View

Read MoreQuick View

Read MoreQuick ViewElectric Valve

- The electric valve is made in Japan, Italy, and Germany.

- It features small volume, high reliability, accurate control of temperature, and is efficient in heat-controlling and energy saving.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewAutomatic Wood Drying Control System (Imported)

- uses HOLZMEISTER, which supports individual programs and is very stable

- Heating, conditional venting and the running direction of the fan are automatically controlled

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewHeating Coil

- The coil uses stainless steel and aluminum bimetallic ribbed pipes.

- The coil is light weight, less resistant to the steam, anticorrosive and high thermal efficiency.

- It is also reasonably designed, fast and easy to install.

Read MoreQuick View